AI Critical Cooling Overview

Data center cooling for artificial intelligence (AI) servers is a critical aspect of modern infrastructure, driven by the increasing computational demands of AI workloads. AI servers, particularly those running machine learning models and high-performance computing tasks, generate significant heat due to their dense configurations and high-power components, such as GPUs and TPUs. Traditional air-based cooling methods often struggle to keep up with these thermal loads, leading to the adoption of more advanced cooling technologies. Liquid cooling, including direct-to-chip and immersion cooling, has emerged as a preferred solution, offering superior heat dissipation and improved energy efficiency. These methods allow for higher server density, reduced energy consumption, and lower operational costs, making them essential for AI-driven data centers.

The rapid growth of AI applications, such as generative AI, large language models, and real-time analytics, has intensified the need for efficient cooling systems to maintain optimal performance and hardware longevity. In response, data center operators are investing in sustainable cooling strategies, including the use of renewable energy sources, AI-driven cooling management systems, and heat recycling technologies. Additionally, innovations like rear-door heat exchangers and hybrid cooling systems are gaining traction to balance efficiency with scalability. As AI server demand continues to rise, effective cooling will remain a key factor in ensuring reliability, minimizing downtime, and reducing the environmental impact of data centers.

AI Cooling Fluid Quality – Key Performance Indicators

Critical cooling fluid measurements are essential for ensuring the efficient and reliable operation of AI servers in data centers. These measures help monitor and control the cooling system, preventing overheating and maintaining optimal performance.

Industry guidelines (i.e. ASHRAE and others) for fluid quality in critical cooling systems for AI data centers emphasize maintaining optimal water chemistry to ensure long-term reliability and efficiency. Key parameters include:

- pH Balance

Maintaining a neutral or slightly alkaline pH (typically between 7.0 and 9.0) to prevent corrosion or scaling in cooling loops. - Turbidity Control

Low turbidity levels are essential and critical to quality, as high turbidity can reduce heat transfer efficiency and lead to fouling of critical heat transfer surfaces. - Conductivity Monitoring

Conductivity is monitored to manage dissolved solids that can contribute to scaling or corrosion. - Filtration & Particulate Removal

ASHRAE suggests using fine filtration to remove particulates and prevent clogging in liquid cooling systems, particularly in high-density AI environments. - Corrosion/Deposit Inhibitor and Coolant Residual Control

Maintaining the proper residual of fluid treatment corrosion, deposit and coolant control levels can be a critical element in the fluid quality management program. - Corrosion Rate Monitoring

Corrosion monitoring and reporting of general and localized corrosion via LPR (linear polarization resistance) technology is a key performance indicator in AI critical cooling water systems.

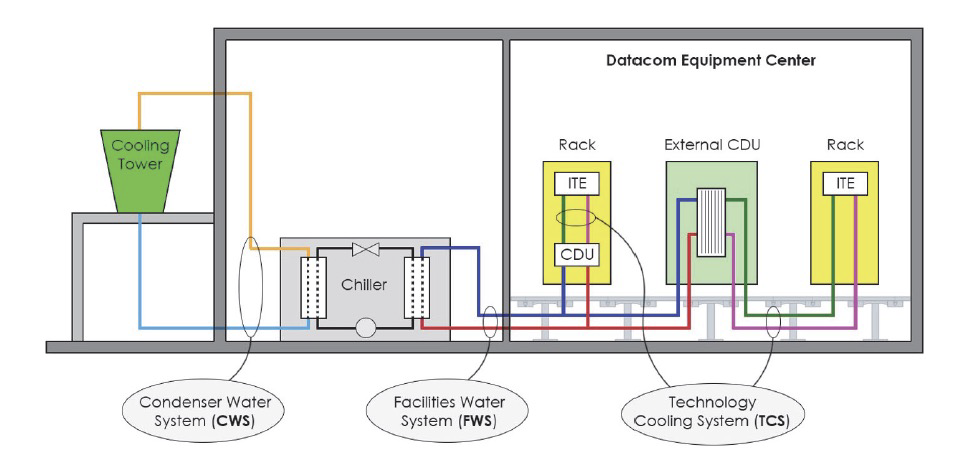

Additionally, ASHRAE recommends using a Coolant Distribution Unit (CDU) to segregate the facility water system (FWS) from the technology cooling system (TCS), improving thermal control and preventing contam-ination. Regular monitoring and transient modeling are encouraged to predict performance under varying loads and ensure system resilience, especially as AI workloads push chip power and thermal demands into uncharted territory.

Pyxis Lab® Smart Sensor Innovations

Pyxis Lab, Inc. specializes in developing and producing advanced water monitoring technologies. The company is a leading manufacturer of specialized ‘smart’ inline sensors, handheld analytical devices, and fluorescent tracing chemicals used across various industries and markets to include critical coolant distribution systems to AI servers. Their technology focuses on improving water treatment operations by offering expanded detection ranges, lower detection limits, and user-friendly interfaces capable of direct communication from sensor to Network or PLC via integrated 4-20mA and RS-485 protocol. With global headquarters near Houston, Texas, and additional offices in Spain and China, Pyxis Lab serves over 25,000 installations worldwide, providing robust solutions for smart fluid management, chemical dosing and process control.

The inline smart sensor platform offered by Pyxis Lab Inc. is ideal for utilization in water and coolant fluid quality monitoring of critical recirculating circuits of the CDU. All Pyxis sensors are 24V DC powered with an average of <1.5W power demand and have fully integrated transmitters within the sensor body/PCB it-self, eliminating the need for any external displays, data loggers or transmitters. This makes the Pyxis line ideal for ease of integration with direct analog and digital (RTU) communication to the site DCS or PLC. Every sensor is also fully capable of direct connection with the uPyxis 2.0 App for digital diagnostics, configuration and calibration when used with the optional Bluetooth/USB adapters sold as an optional accessory.

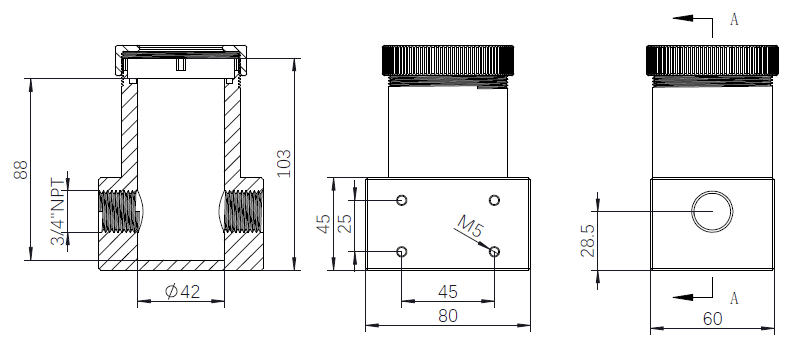

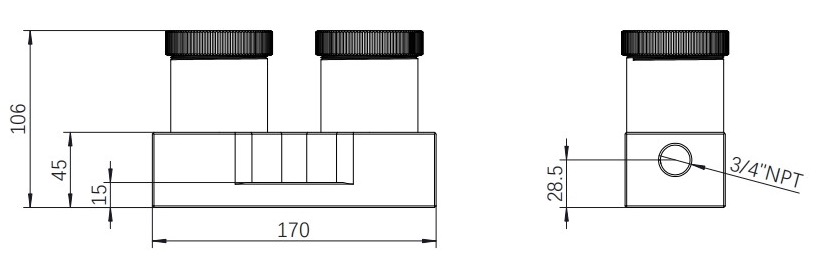

The Pyxis sensor platform is also produced in 316L stainless steel capable of operating at pressures as high as 290psi while installed in the ST-009 series stainless steel flow assembly options. This streamlines installation allowing easy sensor removal for calibration maintenance while ensuring the materials are fully compatible with all segments of the CDU including the Condenser Water System, Facilities Water System and Technology Cooling System.

| Sensor | Part Number | Measured Analyte | Measurement | Material | Install Format |

| CR-300 | 51007 | LPR Corrosion | General MPY/Index | 304SS | ST-009 1in NPT |

| ST-710SS | 53030 | pH | pH | 304SS | ST-009 3/4in NPT |

| ST-711SS | 53031 | ORP | mV | 304SS | ST-009 3/4in NPT |

| ST-712SS | 53032 | pH + ORP | pH/mV | 304SS | ST-009 3/4in NPT |

| ST-720SS | 58761 | Temp. + Conductivity | 1–100,000µS/cm | 316L SS | ST-009 3/4in NPT |

| ST-724 | 10009 | Temp. + Conductivity | 0.02–1,000µS/cm | 316L SS | ST-009 3/4in NPT |

| ST-725 | 53108 | Temp. + Conductivity | 0.02–200.0µS/cm | 316L SS | ST-009 3/4in NPT |

| ST-728 | 53117 | Temp. + Conductivity | 0.02–10µS/cm | 316L SS | ST-009 3/4in NPT |

| ST-500SS-T | 50661 | PTSA Tracer | 0–300ppb | 316L SS | ST-009 3/4in NPT |

| ST-587SS-T | 54386 | PTSA + Turbidity | 0–300ppb/0–200NTU | 316L SS | ST-009 3/4in NPT |

| ST-588SS-T | 53146 | PTSA + Tagged Polymer | 0–300ppb/0–20ppm | 316L SS | ST-009 3/4in NPT |

| ST-565T-SS | 56080 | Tolytriazole Inhibitor | 0.00–10.00ppm | 316L SS | ST-009 3/4in NPT |

| ST-730SS-T | 56377 | Turbidity | 0.0–100.0NTU | 316L SS | ST-009 3/4in NPT |

| ST-730BSS-T | 51119 | Turbidity | 0–1,000NTU | 316L SS | ST-009 3/4in NPT |

| ST-731SS-T | 55995 | Turbidity | 0.00–10.00NTU | 316L SS | ST-009 3/4in NPT |

| ST-772-T | 53719 | Dissolved Oxygen + Temp. | 0.0–20.0ppm | 304SS | ST-009 3/4in NPT |

| RT-100 PRISM | 55105 | Ethylene/Propylene Glycol | 0.00–100.00% | 316L SS | Flow Cell 3/4in NPT |

| IK-765SS-BP | 41771 | Free Chlorine + pH + ORP | 0–5ppm | N/A | Full Panel Solution |

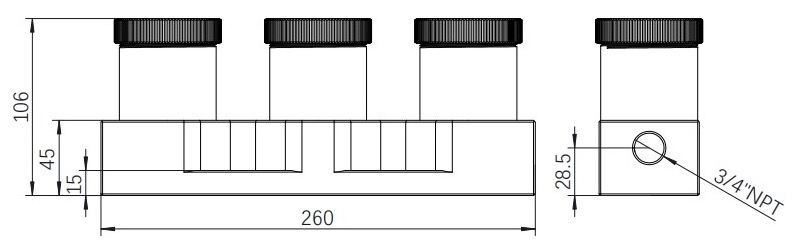

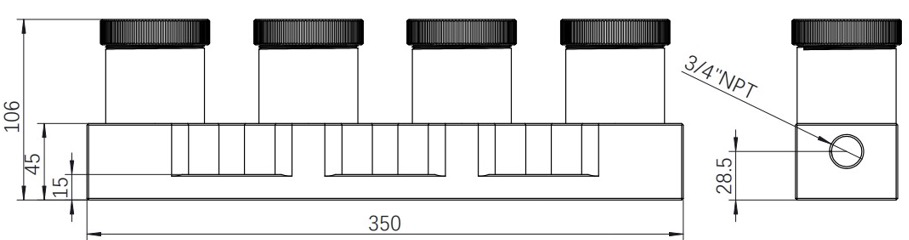

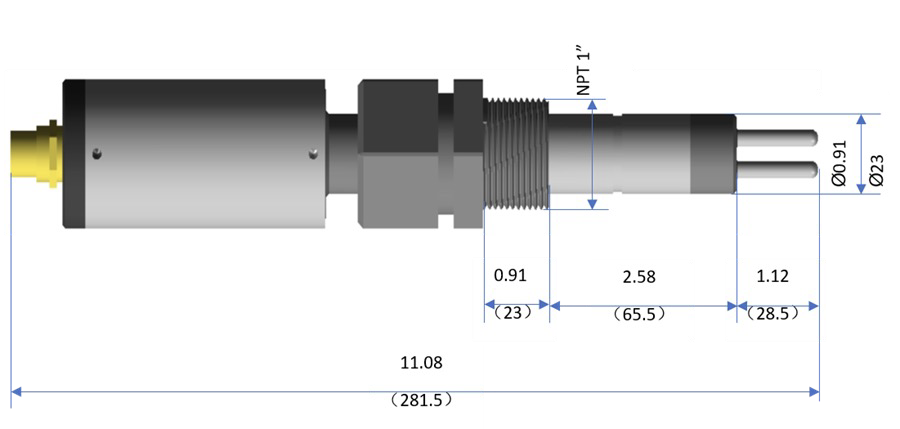

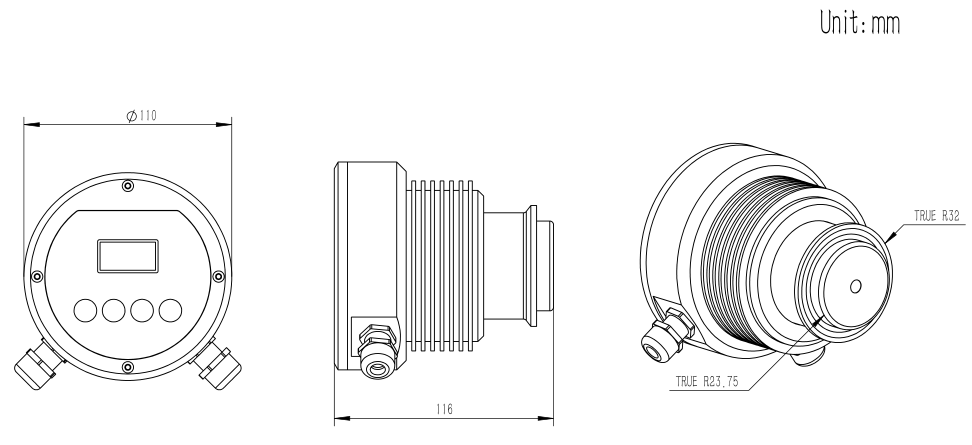

Stainless Steel Flow Cell Dimensions (mm)

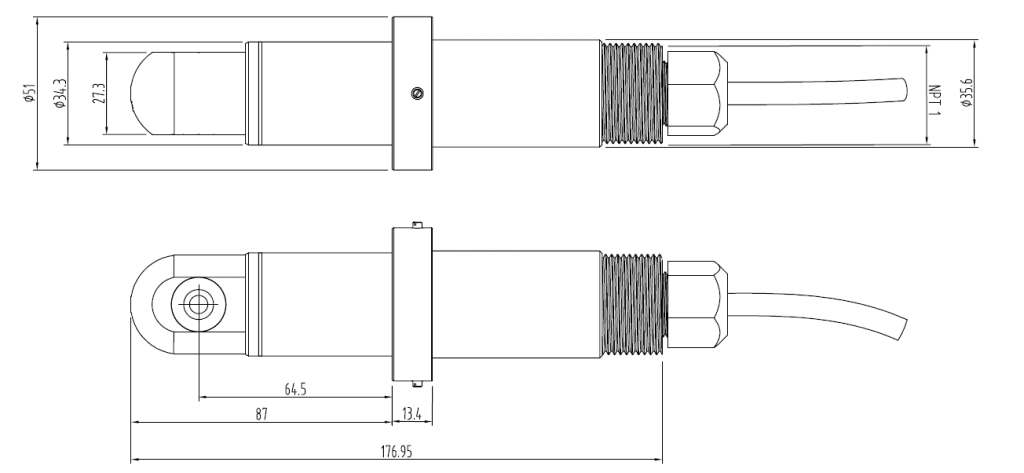

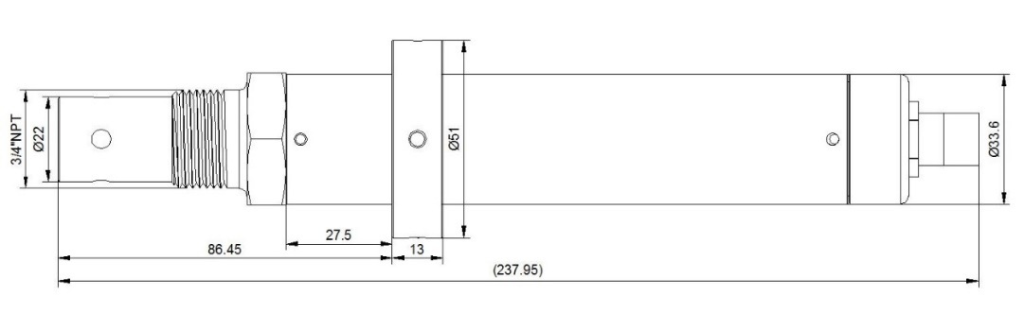

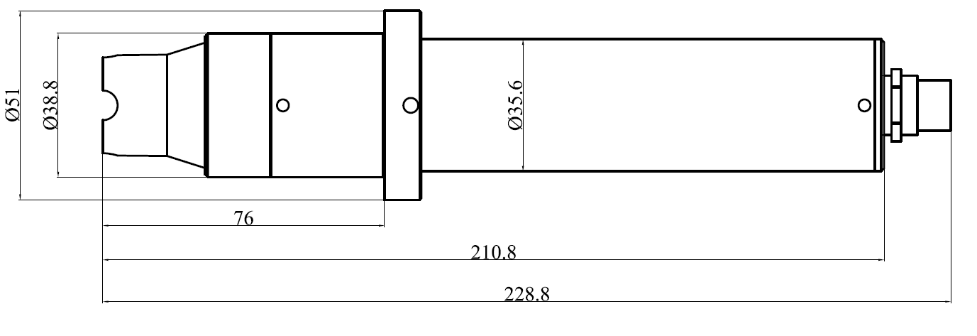

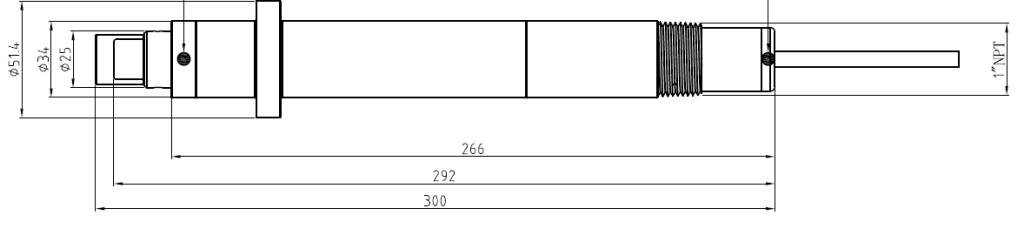

Sensor Dimensions (mm)

Contact Pyxis Lab, Inc.

To learn more about Pyxis Lab smart sensor technologies ideally suited for this critical infrastructure contact us at order@pyxis-lab.com or info@pyxis-lab.com or reach out to us on our website here.