Reverse Osmosis (RO) Desalination

Reverse Osmosis (RO) desalination is a cutting-edge water treatment process that removes dissolved salts, minerals, and contaminants by forcing water through semi-permeable membranes under high pressure. As global water scarcity intensifies, RO has become a critical solution for transforming seawater and brackish sources into safe, usable water for municipal, industrial, and commercial applications.

However, the performance and longevity of RO systems are highly dependent on precise monitoring of key water quality parameters—such as pH, conductivity, TDS, chlorine, ORP, and flow rate—to prevent membrane fouling, optimize chemical dosing, and ensure regulatory compliance.

Pyxis Lab Inc. delivers advanced inline sensor technology, smart analytics, and plug-and-play monitoring systems designed specifically for the challenges of RO desalination. Our innovative solutions empower operators with real-time insights and reliable data to drive system efficiency, protect assets, and achieve superior water quality at every stage of the process.

pH & ORP

Critical in RO desalination to optimize chemical dosing, prevent scaling, and protect membrane integrity. Maintaining proper pH ensures ideal solubility conditions for salts, while ORP helps track the presence or removal of oxidizing agents like chlorine that can damage membranes if not properly neutralized.

Chlorine & Sulfite Monitoring for Dechlorination

Plays a vital role in protecting RO membranes from oxidative damage and ensuring effective dechlorination. While chlorine is used upstream for disinfection, residual levels must be tightly controlled and neutralized with sulfite, which itself must be monitored to avoid overdosing and unnecessary chemical consumption.

Turbidity

Essential for assessing the presence of suspended solids that can lead to membrane fouling and reduced system performance. By tracking turbidity in the feed-water, operators can evaluate pretreatment effectiveness and take corrective action before particulates compromise membrane integrity.

Conductivity

A key indicator of salinity and overall ion concentration throughout the RO desalination process. It enables operators to evaluate membrane performance, calculate salt rejection rates, and verify product water quality in real time.

PTSA Tracer Product

1,3,6,8-Pyrenetetrasulfonic Acid is a fluorescent tracer dye used in RO desalination to monitor and verify the accurate dosing of antiscalants and other treatment chemicals. Continuous PTSA monitoring ensures chemical feed consistency, helps prevent scaling, and supports optimized chemical usage without overdosing.

Smart Sensor Solutions

Pyxis Lab, Inc. sensors are purpose-built for the demanding conditions of RO desalination, combining industrial-grade construction with advanced optical and electrochemical technology. Designed for inline installation and real-time monitoring, our sensors offer exceptional accuracy, low maintenance, and seamless integration—making them ideal for detecting critical parameters like chlorine, sulfite, pH, conductivity, turbidity and tracer dyes throughout the desalination process.

| SENSOR | PART # | MEASUREMENT | RANGE | MATERIAL | INSTALL FORMAT |

| ST-500RO | 50669 | PTSA | 0–40ppb | CPVC | ST-001 Tee |

| ST-710 | 53001 | pH | 0–14 | CPVC | ST-001 Tee |

| ST-711 | 53002 | ORP | ±1500mV | CPVC | ST-001 Tee |

| ST-712 | 53003 | pH + ORP | 0–14, ±1500mV | CPVC | ST-001 Tee |

| ST-722 | 53103 | Conductivity | 0.02–10,000µS/cm | PEEK, Hastelloy | 1″ Thread |

| ST-724 | 10009 | Conductivity | 0.02–1,000µS/cm | PEEK, Hastelloy | 1″ Thread |

| ST-725 | 53108 | Conductivity | 0.02–200µS/cm | PEEK, Hastelloy | 1″ Thread |

| ST-728 | 53117 | Conductivity | 0.02–10µS/cm | PEEK, Hastelloy | 1″ Thread |

| ST-730 | 53201 | Turbidity | 0–100NTU | CPVC | ST-001 Tee |

| LT-737 | 53216 | Ultra-Low Turbidity | 0.000–5.000NTU | 304SS | FR-100/FT-100 |

| LT-737B (EU) | 53224 | Ultra-Low Turbidity | 0.000–5.000NTU | 304SS | FR-100/FT-100 |

| IK-765P-DCL | 49514 | F-Cl + SO3 + pH | 0-5ppm + 0-100ppm | CPVC, Titanium | Panel Solution |

| SENSOR | PART # | MONITORING STAGE |

| ST-500RO | 50669 | Pretreatment and Chemical Dosing Stage or Upstream Return Loop |

| ST-710 | 53001 | Pretreatment Stage and Reverse Osmosis Inlet |

| ST-711 | 53002 | Pretreatment Stage and Dechlorination Verification |

| ST-712 | 53003 | Pretreatment Stage |

| ST-722 | 53103 | Feed-water, Post-treatment and Pre-Reverse Osmosis, CIP Loops, Reject Brine Line |

| ST-724 | 10009 | Feed-water, Post-treatment and Pre-Reverse Osmosis, CIP Loops, Reject Brine Line |

| ST-725 | 53108 | Feed-water, Post-treatment and Pre-Reverse Osmosis, CIP Loops, Reject Brine Line |

| ST-728 | 53117 | Feed-water, Post-treatment and Pre-Reverse Osmosis, CIP Loops, Reject Brine Line |

| ST-730 | 53201 | Post-Intake/Pre-Filtration and Post-Filtration/Pre-Membrane Inlet |

| LT-737 | 53216 | Final Pre-Treatment, Just Before RO Inlet |

| LT-737B (EU) | 53224 | Final Pre-Treatment, Just Before RO Inlet |

| IK-765P-DCL | 49514 | Reverse Osmosis Pre-Treatment, After Chlorine Dosing & Before RO Inlet |

ST-500RO

The ST-500RO-PTSA is a low-range fluorescent tracer sensor designed to measure PTSA from 0–40 ppb in real time, providing precise verification of antiscalant dosing in RO pretreatment systems. Its compact, CPVC construction makes it ideal for inline monitoring with minimal maintenance.

ST-71X pH and/or ORP

The ST-71X Series delivers robust, flat-surface pH and/or ORP sensors engineered for reliable inline measurement in RO desalination and water treatment systems. With durable CPVC construction, replaceable reference assemblies, and resistance to fouling, these sensors provide accurate, low-maintenance monitoring in chemically dynamic environments.

ST-72X Conductivity

The ST-72X Series are high-precision, ultra-low conductivity sensors designed for real-time monitoring in high-purity water and RO permeate applications. Featuring a Hastelloy electrode, integrated temperature compensation, and a durable stainless steel body, the ST-72X sensors offer reliable performance across a wide range—from 0.02 to 10,000 μS/cm—making them ideal for tracking RO efficiency, system recovery, and product water quality.

ST-730 Turbidity Sensor

The ST-730 is a CPVC turbidity sensor designed for inline monitoring in RO pretreatment and filtration systems. With a measurement range of 0–100 NTU, it delivers accurate, real-time detection of suspended solids, helping operators ensure effective filtration and protect RO membranes from fouling.

LT-73X Turbidity Sensors

The LT-737 is a high-precision, ultra-low turbidity sensor designed for clean water and RO permeate monitoring applications. Featuring a 304 stainless steel body and advanced optical detection, it delivers reliable turbidity measurements from 0 to 5 NTU with exceptional sensitivity—ideal for detecting fine particulates and verifying post-treatment water clarity in high-purity systems.

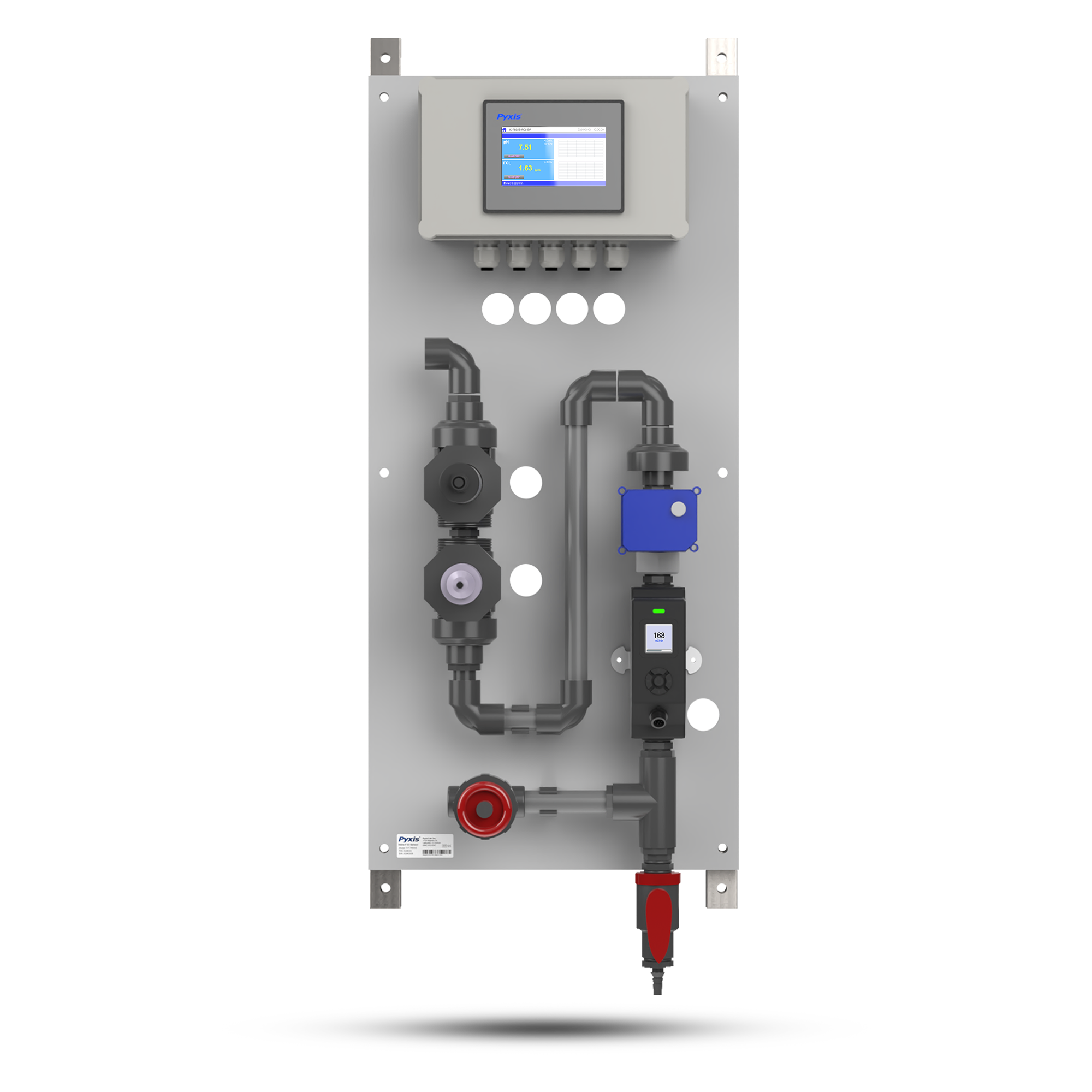

IK-765P-DCL Dechlorination Panel

The IK-765P-DCL is a compact, turnkey dechlorination monitoring panel designed specifically for RO pretreatment applications. It features integrated flow control, a precision rotameter, and a pre-plumbed CPVC flow cell to ensure optimal sampling conditions. The panel includes the ST-500RO PTSA Sensor and the ST-765P-DCL multi-parameter sensor for real-time measurement of Free chlorine, Sulfite, pH, and ORP—delivering complete, inline visibility of oxidant removal and chemical dosing efficiency to protect RO membranes and streamline system performance.

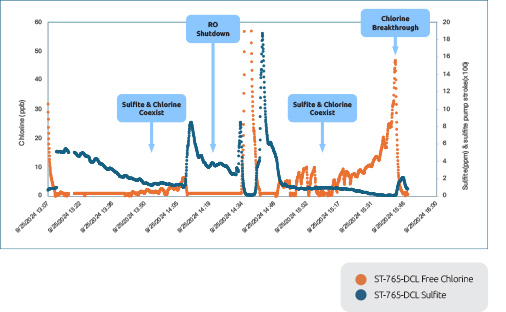

IK-765P-DCL Captured Treatment Trends

The data provided by the Pyxis Lab, Inc. IK-765P-DCL Panel demonstrates the ability to deliver high-resolution, real-time monitoring of both residual chlorine and sulfite levels during the dechlorination process.

In this chart from a customer facility, the panel captures dynamic changes in free chlorine (ppb) and sulfite dosing (ppm), showcasing its precision and responsiveness to fluctuating chemical levels. This detailed insight allows operators to quickly identify dosing imbalances, optimize chemical feed rates, and maintain compliance with regulatory discharge limits—all while protecting downstream RO membranes. The DCL Panel ensures tight process control and data-driven decision-making for critical water treatment systems.

Smart Sensing. Proven Performance.

Pyxis Lab, Inc. sensors are engineered to meet the demanding requirements of reverse osmosis (RO) desalination systems, delivering precise, real-time monitoring of key water quality parameters from pretreatment through permeate. With robust materials like stainless steel, Hastelloy, and CPVC, and advanced measurement technologies including fluorescence, electrochemical, and optical detection, Pyxis sensors offer exceptional durability, accuracy, and ease of integration.

Whether you need to track Free Chlorine, Sulfite, pH, ORP, Conductivity, Turbidity, or Fluorescent Tracers like PTSA, Pyxis provides a comprehensive, modular solution—designed to optimize chemical dosing, protect membrane integrity, and ensure consistent system performance.

Elevate your RO Desalination monitoring with Pyxis Lab, Inc. smart sensor technology. To learn more or request a customized solution, contact us!